Tooling >

Rapid Tooling

Controlling Costs

and Lead Times

With design, tooling and moulding all on one site, our experienced toolmakers and design team offer clients rapid tooling, faster lead times and uncompromised quality.

We understand that outsourcing plastic manufacturing overseas can often mean missing deadlines, poor workmanship, expensive hidden costs and unwanted setbacks.

That’s why our experienced, UK based team are proud to provide a high quality, efficient plastic production service for customers every time, wherever they are in the world.

Bespoke Prototype Tooling

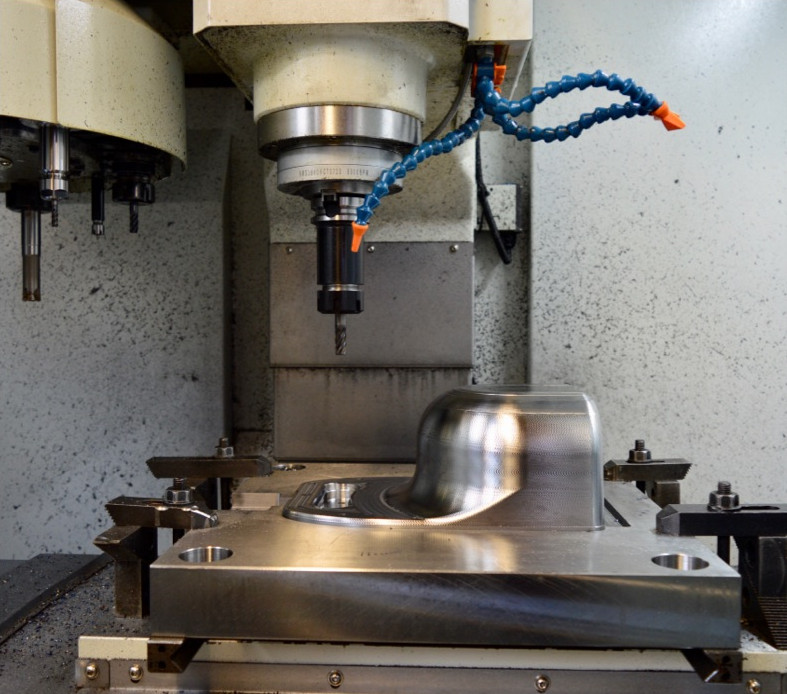

With our combined design, tool material, manufacture and engineering skillset we can efficiently produce bespoke prototypes from new mould tools. Often required for conclusive field testing, where the correct material is paramount, bespoke prototype tooling is frequently the most cost- effective solution for smaller runs, demanding individual attention to detail to ensure value for money without compromising on quality.

Our state-of-the-art equipment (including a 3D printer and scanner for rapid prototyping) and efficient team can significantly reduce your prototype lead times.

Your single point of contact will keep you informed of your project throughout, updating you of progress, recommending innovative improvements and keeping tight control of the costs.

For further information or a

no-obligation quotation simply

contact us today.

Projects