“It would be hard for myself and the Protecting Heroes team to find adequate words to describe our experience working with the team at BEC Group. But I’d start with; Exemplary. Agile. Expert. Problem Solvers. Responsive. Forward thinking. Helpful. Generous. Kind. Working under such pressured and challenging circumstances to produce life-saving PPE, BEC Group have put themselves on the right side of history. Thank you from us at PHCIC and on behalf of the people whose lives they have saved.”

Si Freedman, Protecting Heroes

Project: Critical PPE Face shields for NHS Frontline Staff

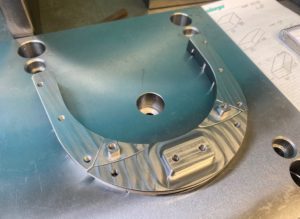

Services: Design for manufacture, moldflow analysis, injection mould tooling design and manufacture. Collaborating to offer a rapid tooling service.

Timeline: 8 days from receipt of approved CAD in our onsite, dedicated toolroom to first off mouldings in our onsite mould shop.

Our Client: Community Interest Company (CIC) Protecting Heroes were set up by experts in the field of rapidly upscaling industrial manufacture, with one purpose. To support the UK effort in fighting COVID-19.

With a design originated by JNDC, the Protecting Heroes team came together to create protective face shields they could manufacture in the UK without putting additional strain on the current health industry suppliers. By partnering with British SME manufacturers like BEC, previously not involved in PPE production, they knew they could concentrate on adding to capacity.

Our Mission: To quickly apply our design, rapid tooling and injection moulding expertise to form part of the stable UK manufacturing base, from which large volumes could be scaled rapidly – to effectively protect front-line NHS staff quickly.

Our Solution…so far: By working closely with Protecting Heroes on the design and manufacture of critical PPE, we were able to move rapidly from concept to manufacture, creating a high quality face shield which simplified the design and production process, passing every rigorous testing obstacle, so that large scale ‘fit for purpose’ industrial manufacture in the UK could be achieved quicker. Applying our expertise to pre-empt any possible pitfalls, plan ahead, include stringent material selection criteria, meet critical timelines and create a mass-production solution.

Having design, tool and moulding expertise under one roof, meant that all aspects of the design for manufacture process were achieved with speed and efficiency. Our huge collaborative effort made sure the design was optimised and the injection mould tooling benchmarks were achieved, enabling us to ensure the end-product complied with the most stringent of accreditations.

Result: First off-shot moulded and once approved, into 24 hour production.

Within days we are proud to have created a fully tested and certified face shield that conforms to the original parameters set by senior figures in the NHS, Ministry of Defence procurement, DFID, testing houses and Parliament.

Manufactured in the UK, safe, rigorously tested and in regular supply.

If you are looking for a UK manufacturer to help to take your product concept through a rigorous design for manufacture review process, in a matter of days, please give us a call.

In the Designer’s Words: “Working on a COVID related project meant everyone in the team needed to focus and deliver. BEC stepped up to the challenge and not only delivered first time to quality, but also delivered early! Offering technical input into materials selection as well as detailed design feedback to reduce the risks to tooling and the end product. Their input meant that the first tool was to specification, with absolutely no modifications needed. Incredible effort by all. Thank you to everyone involved in the project. We look forward to working with BEC again in the future.”

Dean Carran, Founder and designer at JNDC

Our Director, Geoff Elvy, has the last word: “The validation process, normally achieved after a few rounds of testing and tweaking, has confirmed that our face shield design conforms to the latest, stringent requirements specified by the government to supply to the NHS, first time around.”