Tooling >

Injection Mould Tooling

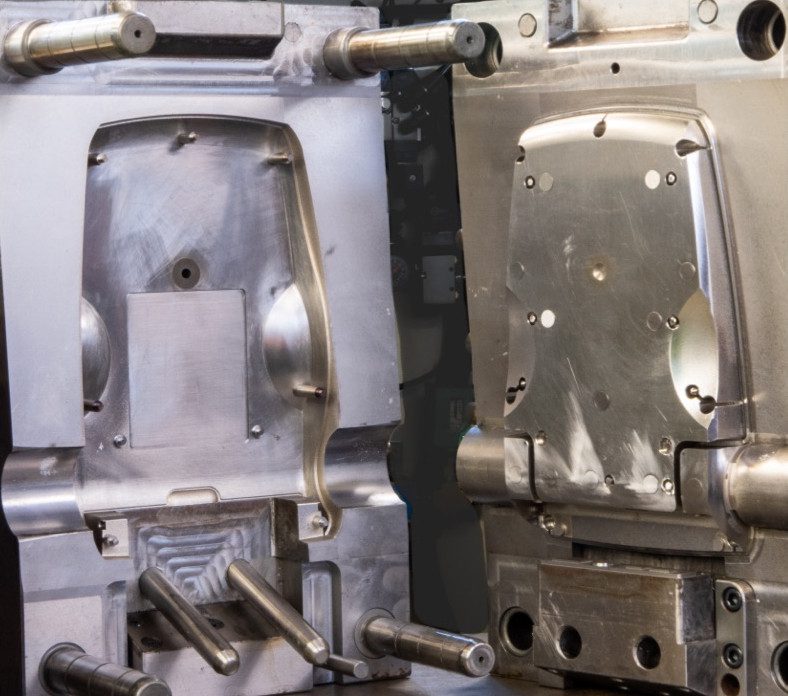

In-House Toolmaking

Our team of skilled engineers offer high quality in-house toolmaking across a comprehensive range of tooling and moulding services. Our toolroom comprises a full suite of the latest machinery, based next door to our extensive mould shop for seamless manufacturing.

With over 40 years’ experience, we have the hardware and skills to design and create mould tools for the most complex parts. With an eye for production-ready injection tooling and sampling, tool repairs, modifications, and cost down reviews.

RESHORING YOUR TOOLING

Bring production back to the UK by reshoring your tooling. With increasingly disrupted supply chains and costs, extended lead times and communication issues associated with tooling abroad over the past few years, BEC have worked with several customers to reshore their tools to our UK site.

Our Hampshire based toolroom allows organisations to have better control over their tooling, allowing for quicker signoffs, smooth communication, and transparent costs. Customers can to visit BEC to speak to our toolmakers and discuss their project in person.

For further information or a

no-obligation quotation simply

contact us today.

Projects

Frequently Asked Questions

What material are mould tools made from?

All of our mould tools are made from P20 steel, this tough and versatile steel is ideal for toolmaking as its pre-hardened and gives a nicely polished finish.

Can you help me with my tool design?

Yes, our team are on hand to help with all aspects of designing your moulding and tooling. Whether you have a prototype, CAD or just an idea- we can make it become a reality.

Do I own the mould tool once it has been made?

Yes, unlike some offshore toolmakers, your mould tool is your property. Once you have paid in full for your mould tool it’s all yours – you are free to move it from BEC at any time.

How much will my mould tool cost?

How long is a piece of string? There are many different variables that factor into how expensive your mould tool will be. A more complicated tool with lots of design features will take much longer to produce than a simple design. The best way you can keep costs down is with a DFM, a process for reducing costs by designing out expensive features.

Can I come and see my mould tool being made?

Yes, you are welcome to visit our site in Hampshire to check on how your tool is progressing. Our approachable team will be happy to talk you through the toolmaking process.

I already have some tools in another country, can you make me new tools in the UK?

Yes, BEC Group often help our customers to either bring back their tools to the UK (reshoring), or to create a new suite of tools so that you have a set in the UK (retooling).