helping you achieve product perfection

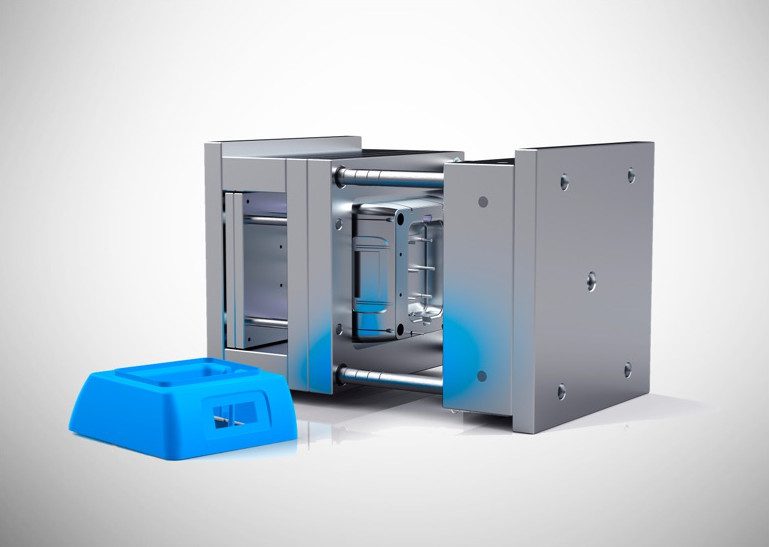

Plastic injection

moulding made simple

Our 40+ years of manufacturing expertise across design, tooling, and moulding make us a great choice for your project. From reshoring and modifying mould tools from abroad, to manufacturing high volume automotive filters to tight deadlines, our team are here to make it happen.

We offer an end-to-end solution on site in the South of England, here you can visit our skilled engineers, discuss every aspect of your design, and watch it become a reality.

Innovative Solutions

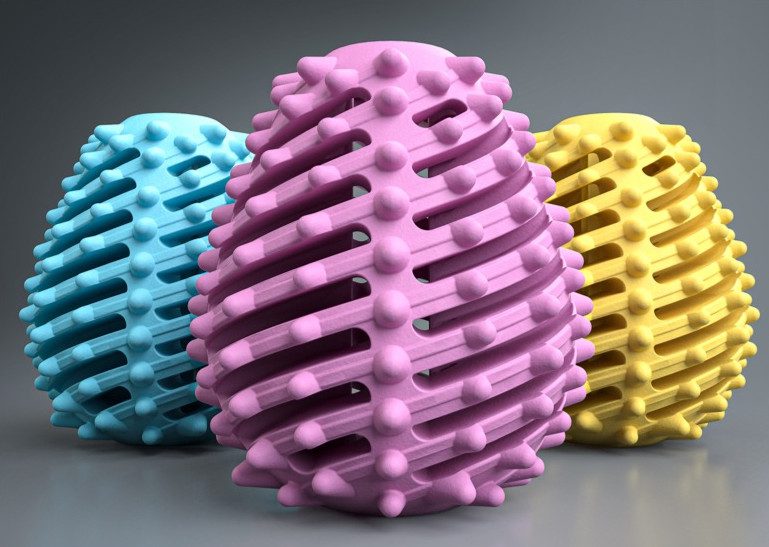

Bespoke Filter Encapsulation

Initially supplying tumble dryer and kettle filters for household names, BEC now produce filters across marine, bio-medical, automotive, transport and FMCG industries. We source and stock a wide variety of meshes including nylon, polypropylene, and ABS.

BEC have been privileged to work closely with forward-thinking buyers and R&D teams across the globe, helping innovators of new machinery and technology produce custom metal, mesh, gauze, and plastic filtration units to their exact specifications.

Streamlined Manufacturing

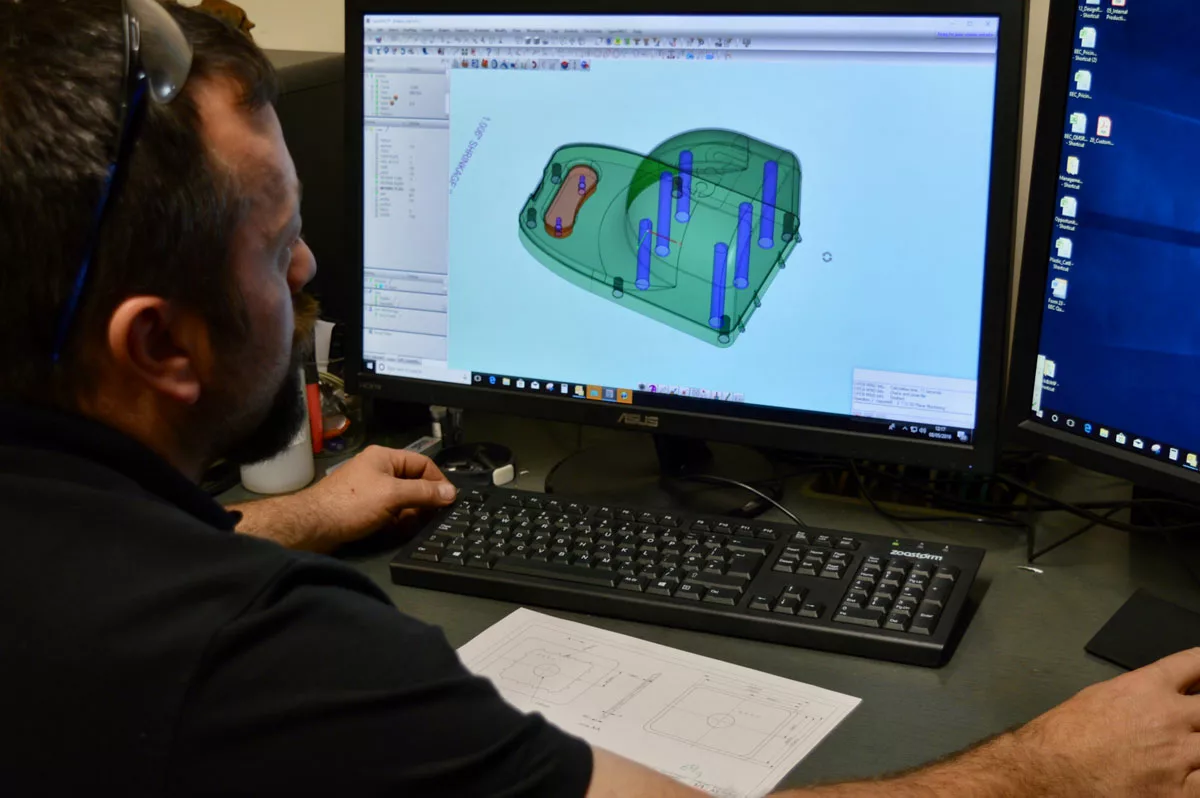

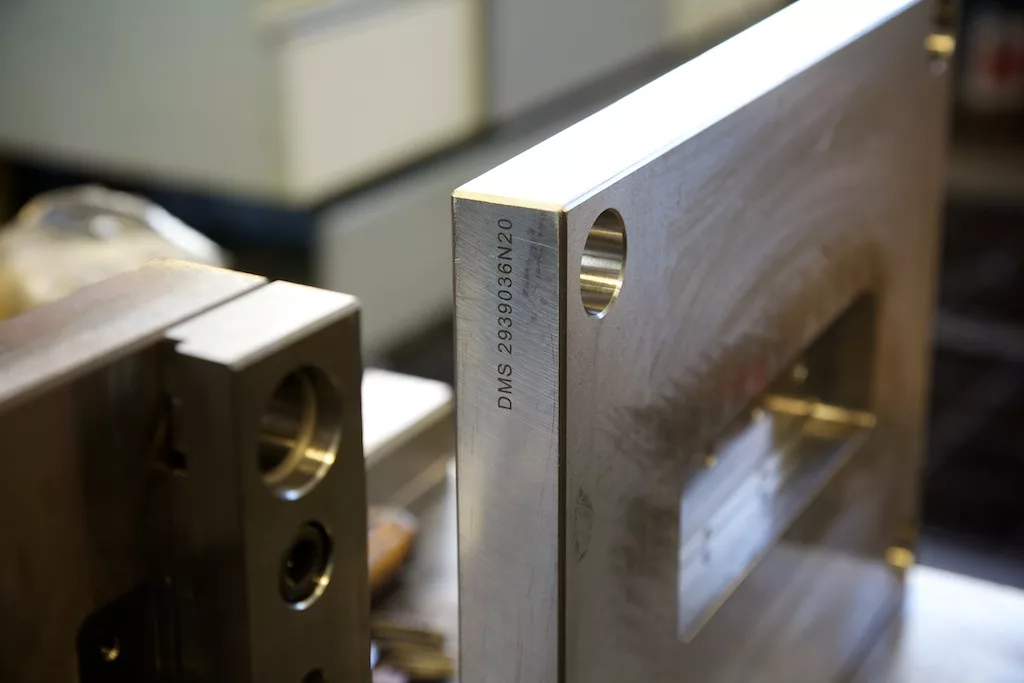

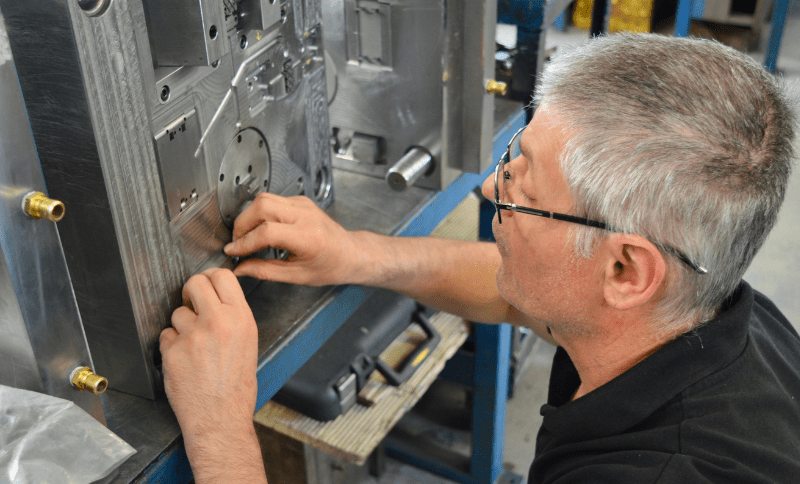

In-house

tooling

BEC specialises in producing high-quality injection mould tooling for global industry leaders, one-man bands, and everything in between. Our skilled toolmakers produce complex and multi-cavity tools, as well as help customers to re-tool or re-shore tools.

Our in-house, Hampshire-based toolroom allows organisations to have better control over their tooling, allowing for quicker signoffs, smooth communication, and transparent costs. Customers can visit BEC to speak to our toolmakers and discuss their projects in person.

Request your Free

sample material card