Design >

Product Design

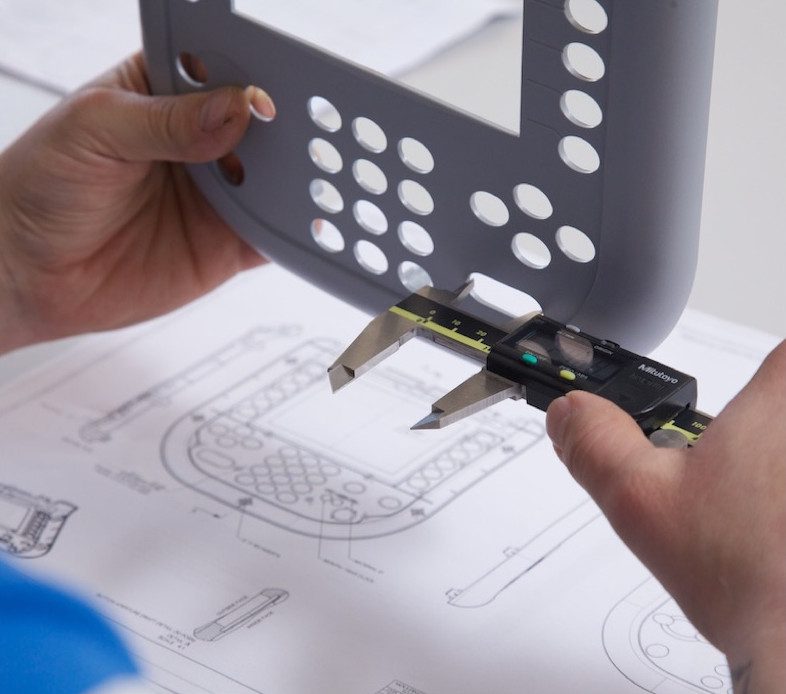

MAKING DESIGNS

MANUFACTURABLE

Product success is ultimately down to great design. Here at BEC we invest time into product design at the outset- to refine it and make it easier to produce, often at a lower end cost.

We consider every aspect of the project, helping with material selection, wall thicknesses and material properties to reduce manufacturing delays and unnecessary rework costs during production.

TOOL DESIGN

Designing a mould tool may be a necessary step in realising your end-product. A benefit of having tooling and moulding on one site is that our engineers work together to make sure your design is optimised for tooling and moulding. Giving you the best design for tooling and moulding at the best price.

Understanding Plastic

From the hundreds of thermoplastic options on offer we can advise you on the most appropriate for your product, taking cost, appearance, tensile strength, impact resistance, shrinkage rates and more into account.

For further information or a

no-obligation quotation simply

contact us today.

Projects

Frequently Asked Questions

I have an injection moulded part but no tooling, can you make me new tooling?

Yes, customers can bring in or send their part to the BEC site; our team will then use several techniques to 3D scan the object- collecting incredibly accurate measurements of every surface at lightning-fast speed. Once this data has been collected it can be pulled across into CAD software and altered, 3D printed, or used to create a mould tool.

I’m not sure if my design is suitable for plastic injection moulding, can you advise me?

Of course, feel free to call or email us and one of our team members will be happy to discuss how your parts are best made. We’ll gladly tell you about the pros and cons of injection moulding for your particular project.

I have an idea or a sketch, but no CAD drawings, can you help me with them?

Yes, our team can produce CAD drawings for your design with some help from you. A sketch of a design with measurements and details/applications will be a good starting point.

I’m not sure what type of plastic will work best in my design; can you advise me?

We can certainly help. Your material selection will depend on what is required for your part- flexibility, impact resistance, toughness and more. We will be happy to offer our opinion on what will work well.

I’d like to keep my design private; would you be happy to sign an NDA?

Many of our customers (big and small) use NDA’s to ensure total privacy. We’ll be happy to enter into one with you.

I need a filter made for a specific space and use; can you design it?

Yes, get in touch and discuss the details of the filter and we’ll be happy to help you with your design. We manufacture filters for tiny fuel particles and large debris alike, working with woven, non-woven and stainless steel meshes.