Tooling >

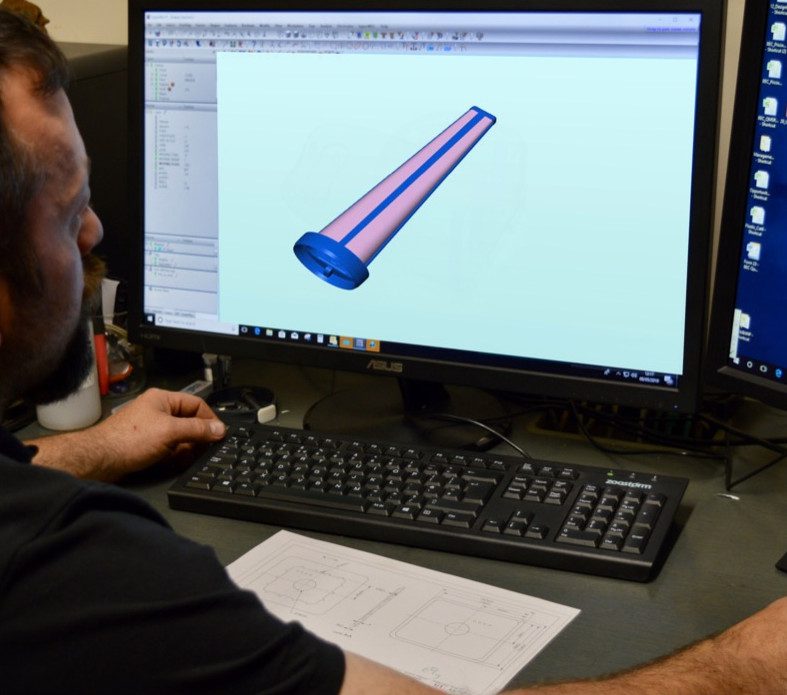

Filter Tooling

Filter Innovation

Proud to be at the forefront of filter innovation for the past forty years, our expert team have developed tooling for a huge range of customised filters, helping clients ensure the smooth running of technology and machinery in domestic and commercial applications.

With the flexibility to produce multi-cavity tool options, we advise clients on the most efficient way to get the most from their mould tool and deliver the quantities of components they require to their timescales.

Manufactured Precision

With a large proportion of our plastic injection moulding output concentrated on plastic encapsulating filters, we ship over 250,000 custom-made filters for the automotive industry to the USA alone, every year.

Offering clients availability, expertise, and specialist knowledge to manufacture the product tooling to their specification, we advise you on the best materials for the application, testing and trialling plastic or metal frames with mesh nylon, metal or plastic gauze.

For further information or a

no-obligation quotation simply

contact us today.

Projects