Producing a mould tool can come at a large expense. Whilst this initial outlay is worth it due to the economies of scale that come with producing hundreds of thousands of plastic mouldings, avoiding unnecessary costs during the process is still important.

A design for manufacture (or DFM) is one of the most important tools in a toolmaker’s arsenal to design out expensive features for the customer. Listening during this process could save you thousands of pounds. Aside from the DFM, here are some of BEC Group’s top tips to save you precious pounds when producing your tooling.

Selecting your surface finishes

How much do you want that shiny, sleek finish? Polished mouldings without imperfections will need to be spark finished or shot blasted, this is an additional cost. If your moulding has surfaces that won’t be seen, consider a natural finish to reduce overheads.

Perfecting the draft angle

In manufacturing, time is money! A quick cycle time will reduce the amount you pay to produce your mouldings. To reduce cycle times, parts need to be ejected quickly from the tool once moulded. A suitable draft angle allows for these parts to be ejected easily without damaging the part.

Designing more than one cavity

If you’re looking to produce a high volume of mouldings, then making a multi-cavity tool might well save you money in the long run. A multi-cavity tool as the name suggests has more than one cavity to form a moulding in. This can make between two and ten mouldings depending upon the size of the cavity. While the initial outlay of a multi-cavity tool is more than a single; it will produce more parts in the same cycle time and is more cost efficient than producing a second tool to increase volume.

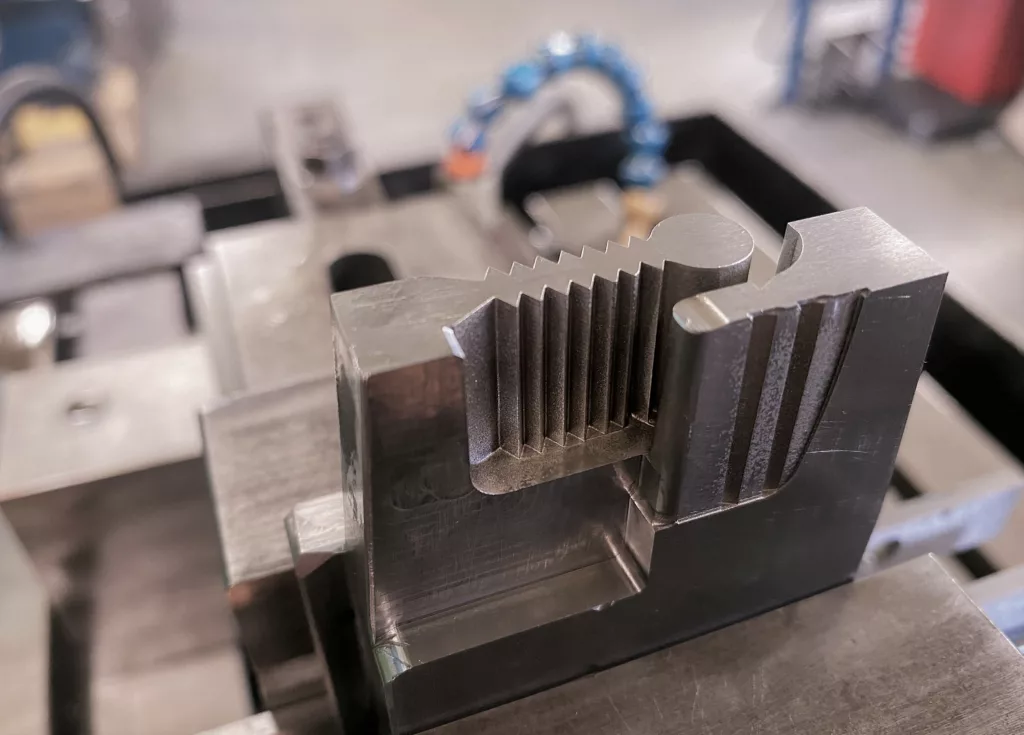

Removing undercuts

Undercuts are features in a moulding that prevent it from being easily ejected when the mould tool opens. Undercuts might be included to provide a handle, a design feature, or allowing for two pieces to snap together easily. If you’re trying to reduce the initial spend on your tooling, undercuts are best avoided. Undercuts make moulding more complex, time consuming, and include more maintenance.

Machining vs. tooling

If your moulding requires side holes, then you would be wise to consider volumes. If you only expect to produce a small number of mouldings, then these side holes could be milled individually. On the other hand, if you’re expecting to produce thousands of parts, then implementing a slider during the tool design will save you money in the long-term despite the initial outlay.

Utilising secondary operations

Depending on the quantity of mouldings you will be producing from your tool it might be advantageous to rely on secondary operations such as milling or machining to achieve the same end-product. If you are manufacturing a low volume of mouldings the cost of these secondary operations will be less than the cost of building the features into the initial tool.

Picking the right partner

Selecting the right partner to work with when producing tooling and mouldings is key to your success and bottom line. Experienced toolmakers will be happy to guide you through a DFM to help you save time and money on your tooling. Using a non-UK based toolmaker may seem cheaper initially but could lead to higher transport costs and the tool may in fact not be yours at the end of the process.

If you’d like to know more about the tooling process or getting in touch with our toolmakers to start a project, then email hello@becgroup.com or call us on 01425 613 131.