What is overmoulding?

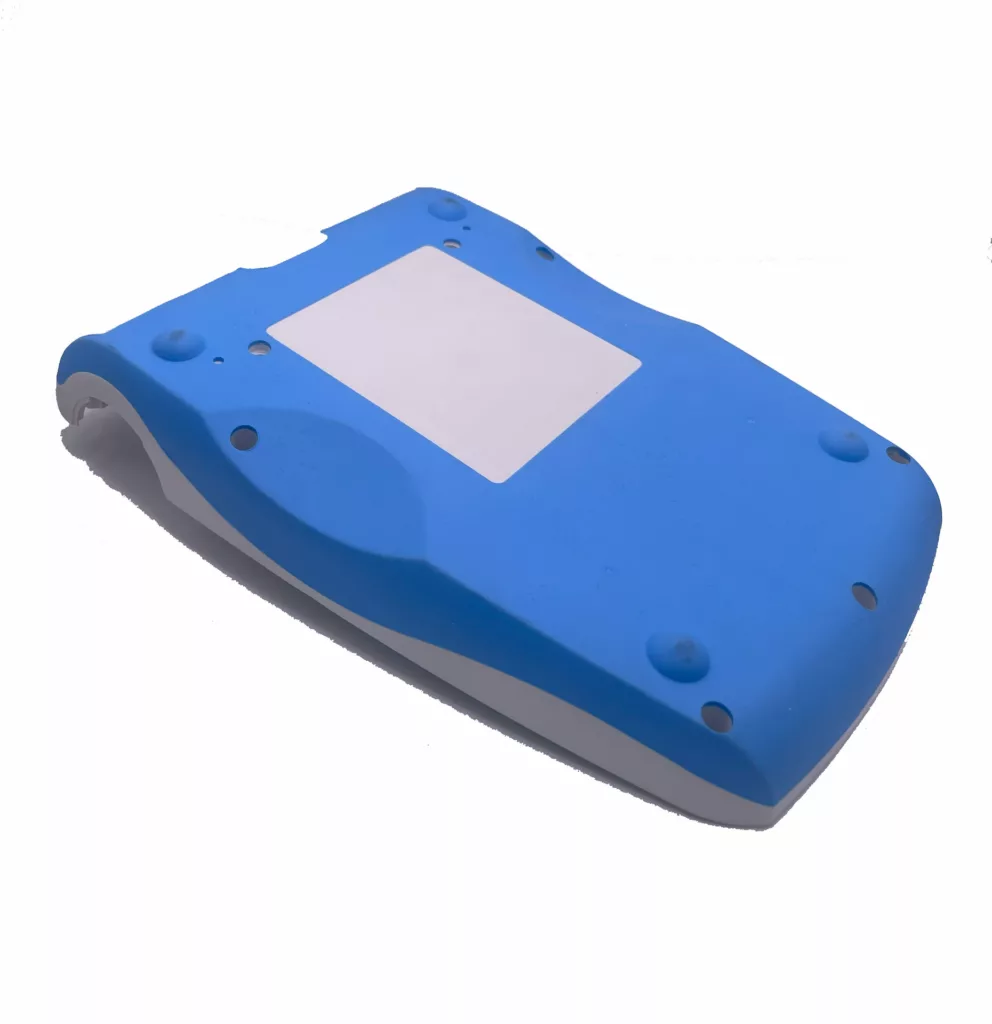

Overmoulding is a method of plastic injection moulding that moulds one component over another. It is often used to make tools easier to grip and use, improve resistance against water, heat, or impact and to give a more attractive appearance.

How does it work?

A base component or substrate is injection moulded, allowed to cure, then a second layer is moulded on top of the first to produce a single part.

What applications use overmoulding?

Overmoulding is often used for applications with rubber or TPE handles such as a toothbrush, or power tool to make the design more ergonomic and comfortable. Industries that often use overmoulded products include:

- Kitchen utensils

- Power tools

- Medical devices

- Surgical devices

- Consumer electronics

What materials are used?

Typically when overmoulding the substrate is made of a harder material such as:

The elastomer moulded on top of the substrate is most commonly:

- TPU

- TPE

- TPR

- Silicone

What are the benefits of overmoulding?

-Reducing the cost of production, as there is no need for post-production assembly

-Improving the water resistance of a part

-Providing a part with electrical insulation

-Adding an ergonomic grip to products for ease of use

-Adding extra decoration through the use of different colours or materials

-Reducing vibrations- for instance through a rubberized grip on a power tool

-Improving impact resistance

-Improving flexibility

What are the limitations of overmoulding?

-Overmoulding is not usually a good option for low-volume production runs due to time and cost efficiency.

-Consideration should be given to the types of plastic used, as not all thermoplastics and elastomers will adhere to each other.

If overmoulding isn’t quite right for your project but your part has a metal component, for instance a dial or screwdriver, then insert moulding might be a better option. Find out more about insert moulding here.