Filter Manufacturers

Filter Services

we offer

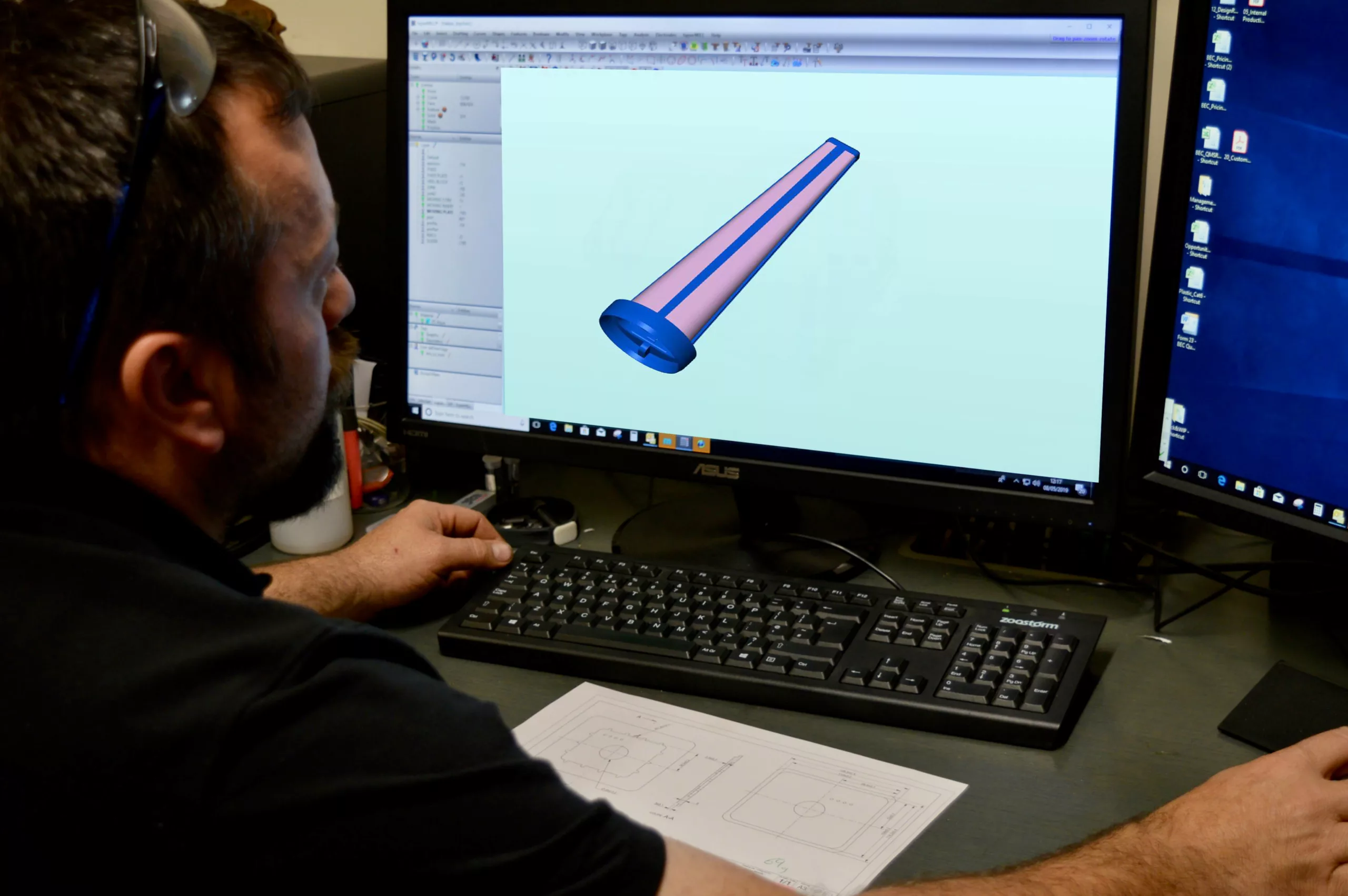

Customers approach BEC at different stages of the filter manufacturing process; some need to change moulders and have a filter and design ready to go, others need assistance in material selection and some guiding through a design from start to finish. We are here to help at any and all stages, advising on design and material selection, prototyping with 3D printing, tooling, and filter encapsulation.

Our site in the South of the UK produces hundreds of thousands of filters for our clients every year. Customers often visit the factory to discuss current and new projects – allowing us to work closely together to design innovative new filters and ensure the quality of current production is up to scratch.

Our Filters

Filters are chiefly used to protect part of a machine– be it a car engine, the heating element of a tumble dryer or the plumbing in your home. A robust filter keeps the machine working for longer.

At BEC, we produce filters for air, oil, water, and solid materials. Using depth-media, non-woven, stainless steel, plastic and sintered meshes ranging from 10 micron to 2000 micron. These plastic encapsulated filtration devices are shipped around the globe, to the Czech Republic, USA, and Germany.

What industries

we work in

Initially producing filters for household goods such as tumble driers and kettles over 40 years ago, BEC has since expanded into manufacturing filters for marine, automotive, domestic, and biomedical applications.

We supply tens of thousands of filters to leading automotive manufacturers every week, for both domestic and large commercial vehicles. We work closely with these clients to develop bespoke filters to fit strict requirements in tough environments.

Our ISO 9001:2015 certification demonstrates our dedication to outstanding customer service and providing consistently high-quality filters to our customers. Our work in serving the automotive industry reflects our ability to keep to tight deadlines and strict quality requirements.

How are BEC filters made?

Manufacturing a filter begins with a tool design for the finished product. Once the mould tool has been produced, a filter mesh is loaded onto a metal core, the steel mould tool closes around it, plastic is injected into the tool and around the filter mesh, encapsulating it in a plastic moulding to create a support frame for the filter.

Post-moulding most filters require some type of secondary operations, be that trimming of excess plastic around the filter, or the more complex ultrasonic welding. Ultrasonic welding involves joining two parts of a filter together through high-frequency vibrations and force. This produces a strong, tight seal without a visible seam.

What materials are they made from?

Material selection is dependent upon the environment and material to be filtered- air permeability, the durability of the filter, and whether a filter can be cleaned or replaced all need to be taken into account when picking materials.

BEC predominantly moulds filters in nylon, polypropylene or polyester due to their chemical stability in air, oil, and water. Depth-media, non-woven, stainless-steel, plastic and sintered meshes are used, ranging from 10 to 2000 microns.

BEC manufactures filters using the following types of mesh/ mesh coatings: acoustic mesh with measured RAYL values, splash and dust resistant meshes, flourcarbon based meshes, hydrophilic and hydrophobic coatings, plasma surface treated mesh.

For more information on our range of meshes and filters please get in touch.

For further information or a

no-obligation quotation simply

contact us today.

Projects

Frequently Asked Questions

Can you help to design my filter?

Our team are always here to help, if you have a partial design, or need advice from start to finish we’ll be happy to assist you. Our team of engineers have been designing bespoke filters for over four decades.

How are your filters made?

BEC produce filters by encapsulating a mesh in plastic. Typically, this is done by loading a mesh into a steel mould tool, clamping the tool shut and squirting plastic around the mesh.

What materials are your filters made from?

The materials used in filters depend upon the environment they need to go in – often nylon, polypropylene and polyester are used to encapsulate the filter as they are chemically stable. The mesh used is typically made from nylon, however we also work with stainless steel and woven meshes.

How large and small particulate can you filter?

Our filters tend to have mesh of between 10 to 2000 micron, this means the holes in the mesh range from so small they’re imperceptible, to big enough to catch rocks and gravel.

What type of filters do you make?

At BEC, we make filters for gasses, solids, and liquids. We commonly make filters for the automotive industry and domestic products such as kettles and tumble dryers. Our more obscure filters help to transport small insects or allow air flow through bricks in houses. Whatever your project we will happily take a look and offer our advice on manufacturing.

I only need a few hundred filters; will you still make them?

We happily produce both low and high-volume product runs. However, the cost of your mould tooling may not justify the initial outlay if you aren’t making a huge amount. Get in touch with the team and we’ll be able to discuss your project in more depth.

Do you ship internationally?

Yes, we regularly ship filters and mouldings across the globe.