As plastic injection moulding specialists, BEC Group’s services are not limited to tooling and moulding; once designs are manufactured our in-house second operations team offer a range of secondary operations. All carried out on site at BEC, these services encompass ultra-sonic welding, printing, chrome plating, hot foiling, trimming and assembly amongst others.

A key secondary operation provided by BEC is heat installing brass inserts. Brass inserts are used in plastic mouldings to provide a non-plastic thread that can be reused within the product without damage from continual assembly and disassembly (such as in a television remote with a case that must be opened to replace batteries). In instances such as these, moulded plastic threads would break or deform through frequent use.

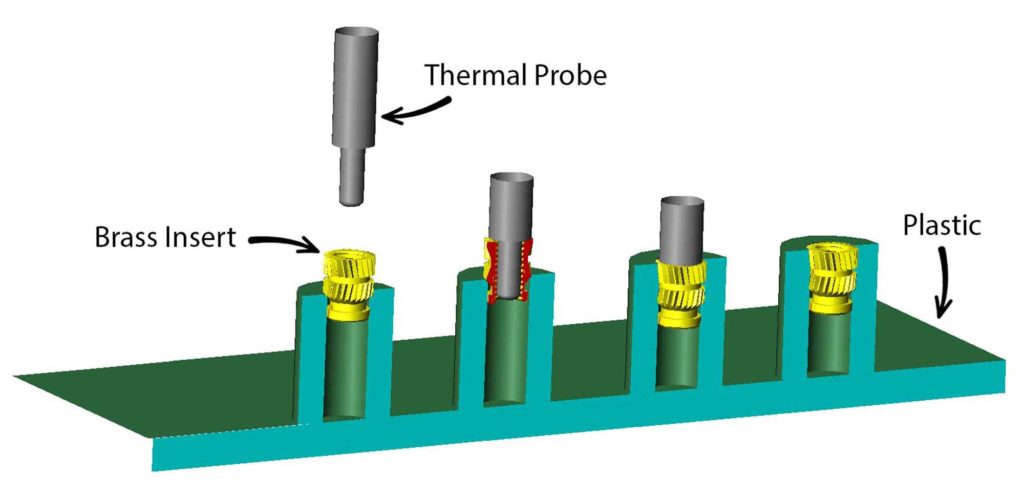

In order to fit brass inserts into plastic mouldings, BEC uses techniques including heat staking. Heat staking works by fitting a brass insert into a hole in the plastic, the brass is heated to a temperature high enough to melt the polymer from a solid to a liquid so that the insert can then be pushed into the plastic until flush. Whilst heated, the plastic flows around the edges and undercuts of the insert to form a tight fitting between the two. Upon cooling, the components are mechanically retained and incredibly difficult to remove.

Above: The process of heat staking

This method is advantageous in that it provides a strong and accurate metal thread for repeated use, without leaving cosmetic damage on the moulding. Other methods of brass insertion such as ultrasonic heat staking whilst effective can increase costs due to added machining prices. Cold insertion techniques (involving pressing inserts into the mould without heat) whilst low-cost, have a lower pull-out force and can cause stress cracking.

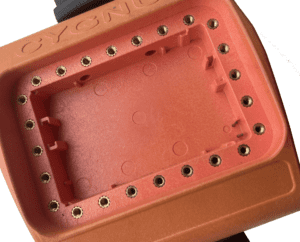

Above: An example of heat staking

At BEC, heat staking is used for a variety of projects spanning medical devices, transportation, electronic casings and payment systems. The image above illustrates the application of heat staking in a moulding.

If you’re looking for an established UK manufacturer to help with you next specialist plastic injection moulding project please get in touch on 01425 613131 or email.