As plastic injection moulding specialists, BEC Group’s services are not limited to tooling and moulding; once designs are manufactured, our in-house second operations team offer a range of add-ons to finish your project. All carried out on site, these services include ultrasonic welding, printing, hot foiling and assembly amongst others.

What is it?

Ultrasonic welding is the process of using high frequency ultrasonic vibrations to weld two materials together. A welding sonotrode (usually made from steel, aluminium or titanium) uses mechanical vibrations that cause friction between the two materials by rubbing them together- raising their surface temperatures. This frictional heat allows the materials to bind to one another, creating a solid-state weld. This process is incredibly quick (usually less than a second) and is perfect for mass production.

How is it used?

In the plastic injection moulding industry, ultrasonic welding is used as a secondary operation across sectors such as automotive, medical and electronics among others. BEC Group utilises ultrasonic welding across food and drinks mouldings, assembly of enclosures and filters for automotive and FMCG among others.

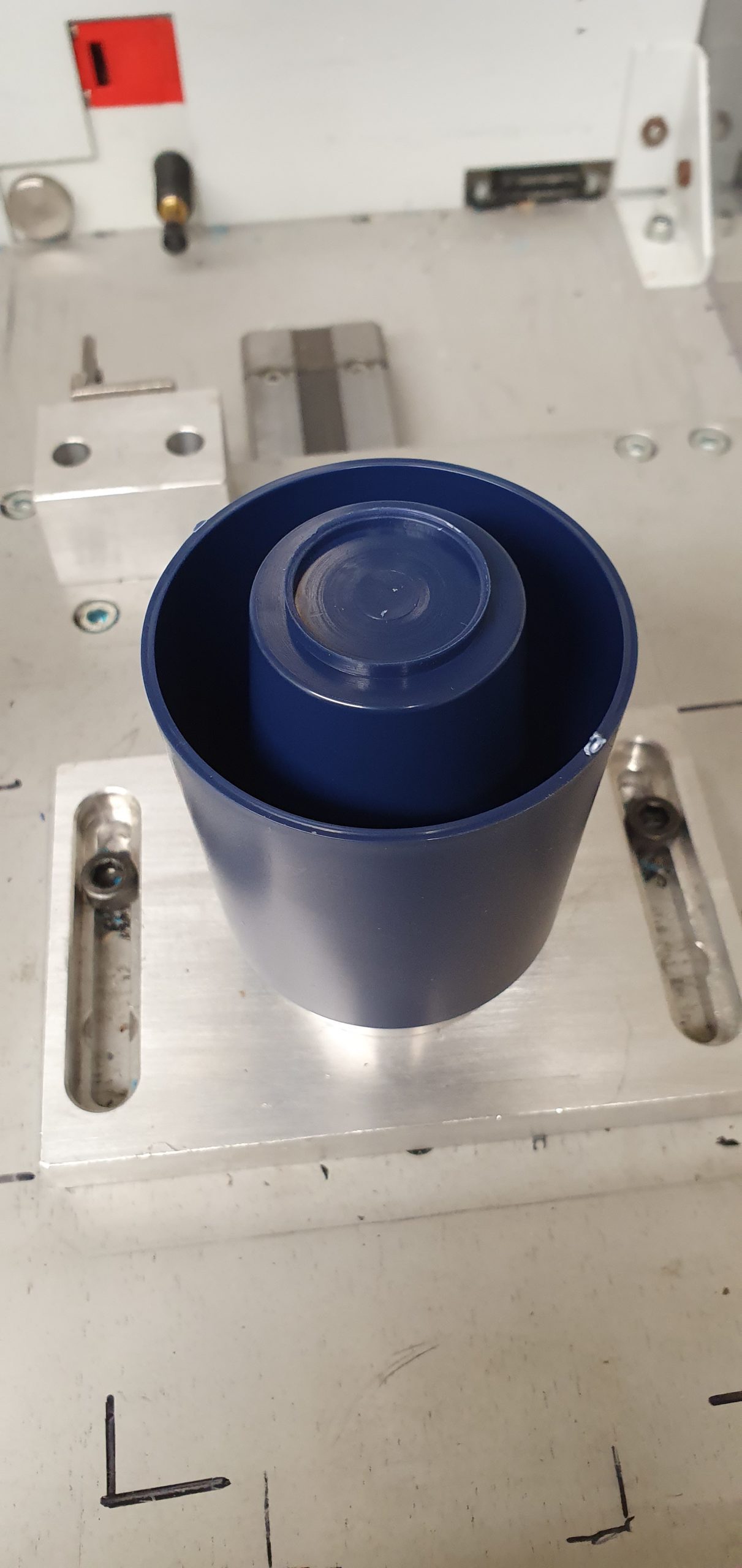

The image below demonstrates a plastic moulding manufactured by BEC for use with hot beverages. Ultrasonic welding was used here to attach two parts of a design with a clean, attractive finish. This method also reduces the labour and expenses that more traditional methods of attaching the two parts would entail.

What are the benefits?

Benefits of ultrasonic welding include the lack of fixings (and their added production costs) such as screws, clips or adhesives. Ultrasonic welding creates a smooth, tight seal without seams or thermal distortions. The process is low energy usage, highly automated and repeatable- ensuring consistent quality in comparison to many manual processes.

If you would like to know more about our secondary operations or need help with a project from our experienced team, get in touch. Either call 01425 613131 or email. We’re happy to help!