BEC Group’s upgraded 3D scanner and printer suite is a quick, cost-effective solution for reverse engineering parts.

What is reverse engineering?

Reverse engineering through 3D scanning is a brilliant way for customers to recreate or amend legacy parts they don’t have CAD or digital drawings for. Whilst CAD drawings can be easily altered, if customers don’t posses or can’t access them, they often must start the drawings from scratch. Advancements in 3D scanning and its accuracy now means there is a great alternative available.

How does it work?

Customers can bring in or send their part to the BEC site; our team will then use several techniques to 3D scan the object- collecting incredibly accurate measurements of every surface at super-fast speed. Once this data has been collected it can be pulled across into CAD software and altered, 3D printed, or used to create a mould tool.

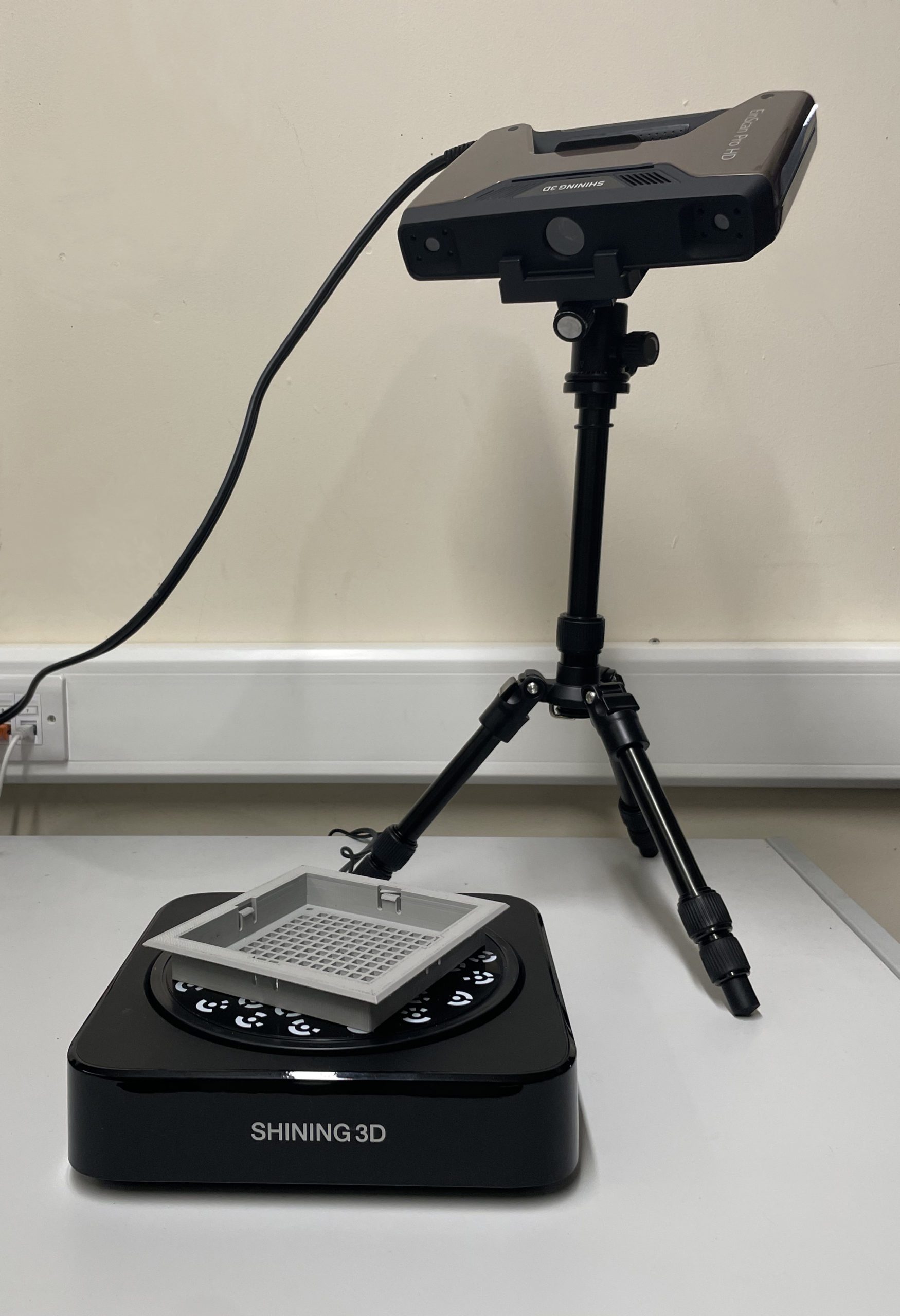

Image right shows a legacy part brought into BEC which was 3D scanned on site, turned into CAD and 3D printed as a prototype.

What are the benefits?

3D scanning is a relatively quick process (although this is dependent in part on the complexity of the object), often making reverse engineering a quick and cost-effective solution. 3D scanning is also much more accurate than manual measurements, particularly on awkward or difficult to measure shapes.

What projects can it be used on?

Our 3D scanning equipment is incredibly versatile and can be used on different sized parts, materials, and surface finishes. Our team will be happy to discuss any questions surrounding this with you.

3D scanning can be tricky on damaged parts, however with the correct technology, preparation of the part and expertise even these can be reverse engineered.

Get in touch to find out more about reverse engineering or to discuss a specific project. Email hello@becgroup.com or call 01425 613131