Rapid Tooling: what is it?

Rapid Tooling: what is it?

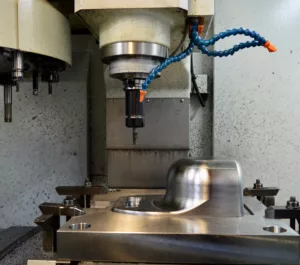

Rapid tooling as the name suggests focusses on producing a mould tool for customers quickly. Whilst many toolmakers do carry out rapid tooling for customers, the materials, processes, and end results can vary greatly between companies.

At BEC Group we use rapid tooling to give customers a great quality tool in less time than our standard model. As with all tooling at BEC, the mould tools are tailored to each customers’ requirements and applications.

How do BEC Group carry out rapid tooling?

BEC carry out rapid tooling by creating development tools, allowing for minimal initial outlay before we approve the tool and perfect the design. A development tool uses the same techniques for production as a standard tool, but with several all-important tweaks.

Most important of these is the design for manufacture or DFM. Our toolmakers use the DFM to evaluate every aspect of a design and whether it is necessary. By outlining options to remove small inefficiencies, machining times and we can hugely reduce costs. For instance, by changing sharp corners on a design for curved, it negates the need for sparking- reducing lead times on a tool by 25%. Changing automatic sliders for semi-automatic can also reduce times and costs initially. However higher labour costs for moulding mean this is best used only in the development tool.

Producing a single cavity tool over a multi cavity tool could also save time and therefore cost but may mean a multi cavity alternative is produced to run in tandem with the development tool once it has been signed off – to further increase moulding production.

Once a development tool has been created and first-offs have been tested, customers can decide to continue with production runs from the initial tool which having been produced from tool steel will continue to manufacture high quality mouldings for thousands of runs. Or, if customers wish to speed up production with a typical tool, this can also be achieved through modification of their development tool or through the production of a new one.

When is rapid tooling used?

Rapid tooling suits a variety of situations; manufacturing promotional parts, late-stage prototypes for product testing, testing different materials, accelerating access to market, or producing a decent volume of mouldings as quickly as possible.

What sets BEC’s tooling apart from the rest?

BEC’s method of rapid tooling uses the same steel as our standard tools – P20. This enables us to get tens of thousands of cycles from a tool. Many tool makers use aluminium to produce rapid tooling more quickly (due to it being easier to machine than steel) and at a lower cost – however this shortcut has several drawbacks. The lower tensile strength of aluminium causes it to wear out more quickly than steel, often producing far less moulds over time before becoming unusable. Steel also does not break or distort over time- unlike aluminium. Steel is used with tougher, glass filled abrasive plastic – aluminium cannot. In addition, aluminium is more prone to scratches and surface finish erosion than steel.

Our co-located tooling and mould shop in the South of England is ideal for clients to view their tool. Customers can meet our skilled toolmakers and engineers and make adjustments to their tool design.

If your business requires rapid tooling from flexible, reliable toolmakers with a huge amount of experience, get in touch. Either call 01425 613131 or email. We’re happy to help!