We sat down with our Head of Design & Innovation, Paul Holland, to learn all about BEC’s Design for Manufacture process.

Why is DFM so vital to the success of any plastic injection moulded product?

Why have BEC always done it – without the customer even asking for it?

and

How does it save BEC customer’s money?

Design for Manufacture? It’s hugely important for functionality and optimal manufacturing.

Our DFM process starts the moment we first see a product. It should be called “Quote & Flag” really. We naturally end up flagging potential issues at the design for manufacture stage. Without it, we wouldn’t be able to quote.

Some of the things that need to be considered at this stage are:

- How many do you need to produce?

- What do you want each item to cost?

- What’s the timeframe?

- How important is quality in the time, quality cost balance?

- What type of material is best suited?

- What are the external, chemical, environmental challenges?

- Will it need to withstand water, heat, outside elements?

We don’t design the product; we design a tool for the product to be manufactured.

Key considerations such as unit price, durability, scalability, productionisation (modifying the prototype into a version that can be easily mass-produced) are all taken into account during the DFM. We help designers to avoid any possible issues that could make it tricky or pricey to manufacture further down the line.

We give our advice from a manufacturer’s perspective.

As plastic injection mould manufacturers, we highlight what the designer needs to think about when it comes to plastic injection mould, tooling and production.

We’ve got decades of experience. Plastic injection moulding since Sony released the Walkman, and Maggie became the UK’s first female Prime Minister!

It’s a deep-rooted understanding of plastic injection moulding that helps us to guide designers through the process and offer them the best options for their design so that they can make an informed decision.

By addressing the DFM process at the early stages, this will aid production, for instance creating thinner walls to decrease cooling times and therefore reducing cycle times. For any design to be moulded, you’ve got to start with your ideal “final outcome” and work back.

In many recent projects we’ve faced specific challenges such as; face visors that were quick to market (Protecting Heroes), protective safety equipment trusted globally (Finger Saver), overmoulding circuit boards and using mould flow to protect electronics (Velobleu), and producing large quantities of cabling encased below sea level (Channel Tunnel).

All products which had particular considerations. And all products which benefited from a comprehensive design for manufacture process at the outset.

We work with designers to help them avoid problems down the line.

On a recent look around Bournemouth University’s Museum of Design in Plastics, we had an interesting chat with upcoming designers, discussing what they need to consider when designing new plastic products and how the impact of product design collaboration – a collaborative process with plastic injection mould and tool manufacturers – only results in more successful, effective and marketable products at the customer’s desired unit price.

All it takes is a conversation.

A designer comes up with an idea. Approaches us in the early stages, perhaps with a prototype, or the first early stages of design and we add the plastic injection moulding, material, and tool perspectives – designing out the cost, tooling and production.

Toolmakers and designers, we have the same goal, just from different perspectives. To give the customer what they want.

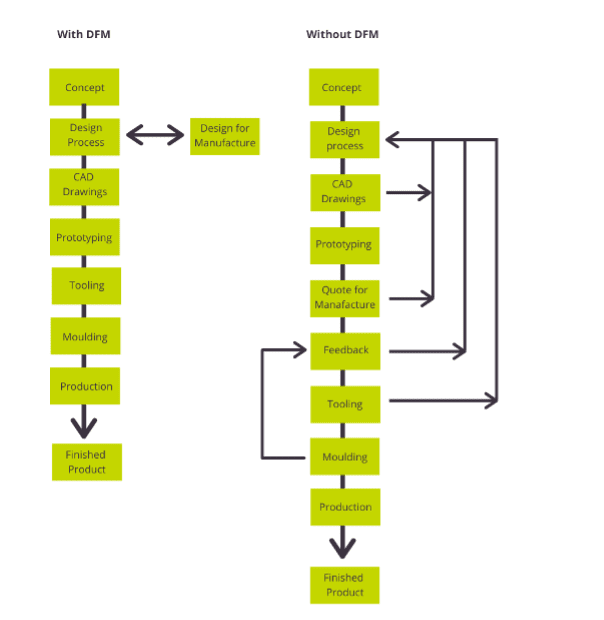

A Project’s concept to delivery is often depicted as a flow chart:

The secret?

Channel your efforts, resources and time early on during the design process and DFM.

Problems are easier to resolve then.

Absorbing as much injection mould manufacturing and tooling input from the process as you can. Resolving issues which could crop up in future with moulding, finalising the optimum tool, selecting materials, positioning gates, split lines, weak points, working out quantities, ideal quality and unit costs. Giving the designer options and getting that design absolutely nailed.

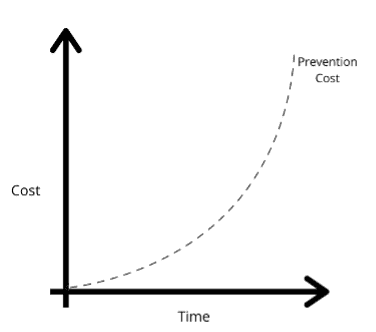

Then and only then are you ready for production. Put the work in early and from then onwards production should be a smooth ride, with your product right first time. The interaction between cost and time throughout the design for manufacture process is pictured below; the longer you leave an issue to be rectified, the more it will end up costing.

My advice? Get the moulding and tooling side of things started straight away.

Problems do happen sometimes. But when they do, we always work to find a solution. Rather than just saying NO, going back to the customer with an alternative solution.

By having all 3 disciplines, design, tooling and moulding under one roof we’re able to give the customer what they want.

Don’t regret getting the answers to more questions early on. Ask us anything or to arrange a tour email hello@becgroup.com or call us 01425 613131 … we’re here to help!

TESTIMONIALS:

Keywing case study

“Giving me insights and advice only experts could know – BEC worked hard to get my product to market so I could achieve my goals. And having the whole process in one place meant I had full visibility from start to finish.”

Geoff Rolandsen, Founding Designer, Keywing

“BEC worked with us to resolve a number of issues and provided an exceptional end-to-end plastic injection moulding service, from under one roof. Being local meant we could visit them regularly, giving us visibility at every stage of the project, making problem-solving quick and easy.”

Martin Dennis, Specialised Engineering Products (SEP)